David Palmer’s Resume

Education:

Old Dominion University, Norfolk, VA

· Masters: Engineering Management, May 2018

· Bachelors: Mechanical Engineering, Aug 2014

Thomas Nelson Community College, Hampton, VA

· Associates: Engineering, Science, Mechanical Engineering Technology, Arts and Sciences, May 2011

Work Experience:

· Mechanical Experimental Equipment Engineer, GS-13, NASA Langley Research Center, (2014-Present)

Position Description:

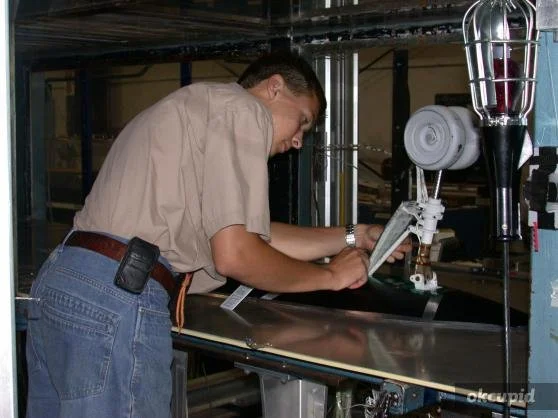

NASA’s 8ft. High Temperature Tunnel (HTT) is one of the most volatile supersonic/hypersonic tunnels in the world. It is a combustion tunnel utilizing methane as its main source of fuel and LOX injection to correct the air molecular composition after combustion. The nature of this environment and the complexity of the facility’s systems creates situations where unique state-of-the-art systems need to be designed, fabricated, and maintained. I coordinate the integration of multi-phase projects into our facility. I provide scheduling, oversight and project management in order to meet customer requirements. I utilize years of my technical expertise to trouble-shoot facility and customer systems in order to provide guidance in developing new procedures, equipment, systems and tools.

The 8ft. HTT is utilized to access, optimize, and provide valuable research support for hypersonic air breathing propulsion and various Thermal Protection (TPS) test articles. I served the facility by providing technical leadership, supervision, training, mentorship, and guidance to the test team of technicians and contractors, as well as, participating in any problem/failure analysis of the tunnel and its subsystems, test article hardware while providing corrective actions to any anomalies identified in the facilities Problem/Failure report process.

I routinely confer with the facility customers in a courteous manner to identify and implement test requirements and to clarify and provide any special requirements or instrumentation needs. I communicate status reports and facility daily tasks in efforts to keep the customer on schedule. I lead customer model integration activities and help troubleshoot to find creative solutions to resolve any oversights that may have occurred.

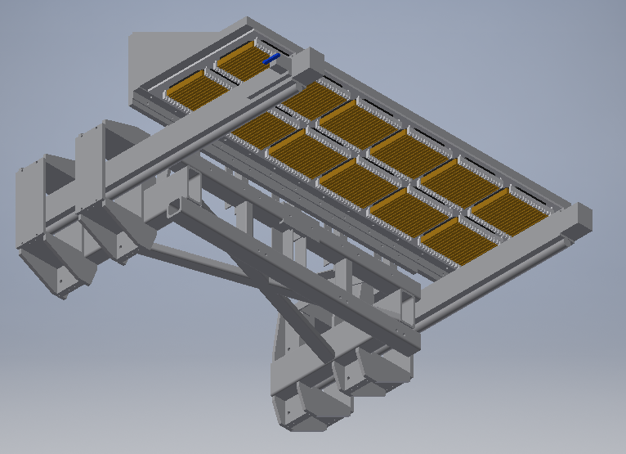

As a Test Team Lead, I always look for opportunities to improve processes, products, services, and reduce cost where possible. As an example of this being an effort to decrease model installation time I designed quick disconnect panels for test article integration that ride up and down on the elevator carriage in the test section.

During test programs I regularly evaluate data looking for anomalies in performance. I document and report findings to management and contractors with recommendations for actions if needed.

I worked full time as well as attend classes at Old Dominion University where I earned a Master’s Degree in Engineering Management and became a member of the Golden Key international honor society.

· Own and operate a small handyman company, US Neighborhood Handyman LLC

I manage and preform small projects for customers around my neighborhood, projects range from pluming/electrical/automotive/HVAC/ and general home maintenance.

· Co-op student, NASA Pathways Mechanical Engineer program, (2011-2014)

Position Description:

As an Engineering Co-op, I became more heavily integrated into the 8ft High Temperature tunnel. I spent years learning from the decades of experience gained by the engineers and technicians that work at the facility. I took on more and more responsibility working more independently to support the test programs that have come through the facility.

I worked full time as well as attend classes at Old Dominion University where I earned a Bachelor’s Degree in Mechanical Engineering.

· Co-op student, NASA Pathways Mechanical Engineering Technician program, (2008 –2011)

Position Description:

As an Engineering Technician CO-OP, I provided technical, mechanical, and operational support to aerospace research conducted in over 12 facilities at NASA Langley Research Center including: Basic Aeronautic Research Tunnel, 8ft High Temperature Tunnel, Material Science Lab, Air Traffic Control Lab, Fab Shop, Calibrations/Measurements Lab, Flight Simulations, and 3D Printing/Water Jet.

I worked full time as well as attend classes at Thomas Nelson Community college where I completed four Associate Degrees, and became a member of the Phi Theta Kappa honor society.

Skills:

· Project Management

· Mechanical Design

· Instrumentation

· Autodesk Inventor 3D Modeling Software

· Fabrication

· Quality Assurance

· Problem Solving

· Communication

· Leadership

Certificates:

· Certified Aerospace Technician

(By: National Science Foundation's National Resource Center for Aerospace)

· Passed Fundamentals of Engineering Exam

· Secret Security Clearance

· Eagle Scout

Community Involvement/Center Improvement/Personnel Improvement Programs:

· ACT 2 Branch Representative: Conveyed the Supersonic Hypersonic Branch center development ideas to center management and representatives from the remainder of Langley’s divisions to promote innovation.

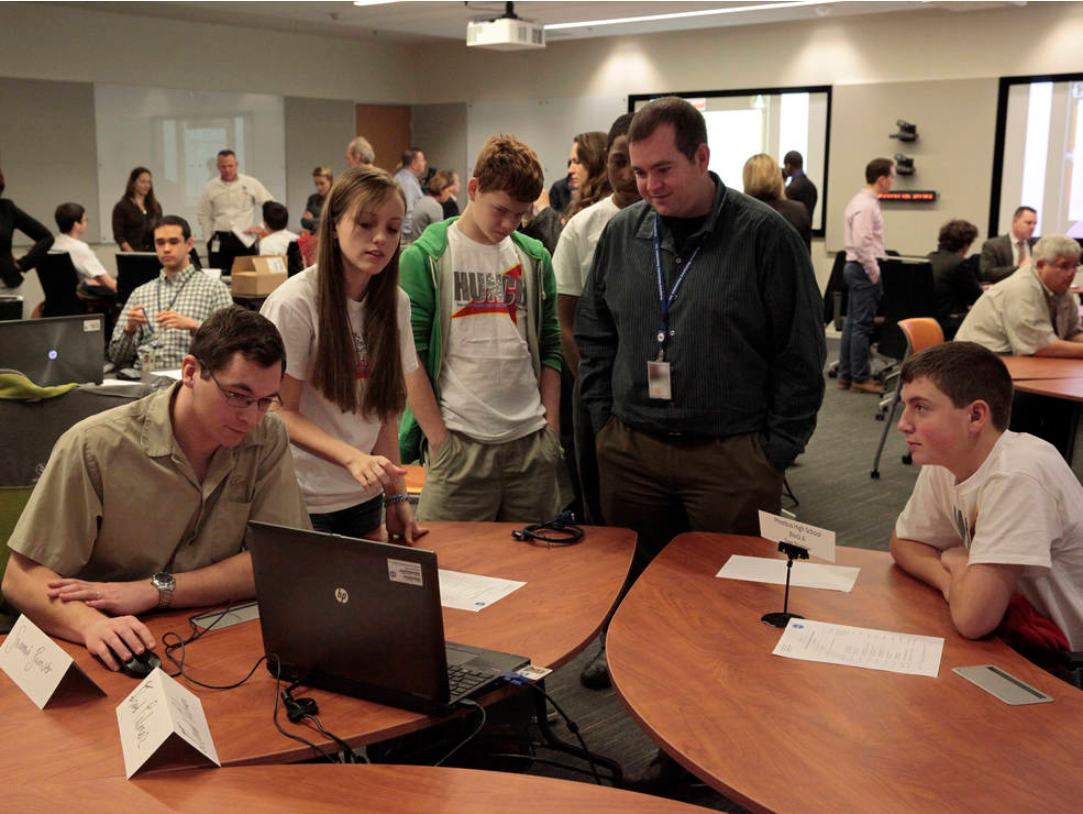

· Hunch Program Mentor: Over period of one semester, guide two high school classes in the design and construction of hardware to potentially be used on the international space station.

· Participant in the GROW program designed to expand participant’s potential to contribute to the NASA mission through exposure to the diverse and knowledgeable perspective gained from working with a multidiscipline team.

· Day of Education Participant: Communicate to local schools about NASA mission, educational programs, and encourage students to pursue a career in Science, Technology, Engineering and Math.

· Served as Counselor & Facilities Commissioner at Bayport Scout Camp

Job Related Training:

· Safe use of Oxygen and Oxygen Systems

· University of Kansas Aerospace Short Course

· Flight Test Engineering

· Flight Test Principles and Practices

· Fire Hazard Training

· Tubing, Piping, Fittings, and Conax Fittings

· Practical Aeronautics: Introduction to Aeronautics

Additional Information:

2025 Group Achievement Award

2020-2024 Individual Cash Award

2019 Individual Time off Award

2019 Group Cash/Time off Award

2017-2018 Individual Cash Award

2017 NASA Honor Award Group Achievement

2016 Group Suggestion/Invention Award

2016 Individual Time off Award

2014-2016 Individual Cash Award

2013 Individual Time off Award

2012 Individual Cash Award

2009-2010 Group Time off Award

Tests at the 8ft. HTT:

2010 Inflatable DE accelerator Thermal Protective System (PAIDAE) Test

2011 Boeing Warm Wing Test, Flexible TPS Calibration Sled, Hi-Fire FSA Test

2012 Large Scramjet Engine Test Technology (LSETT), Navy HBW Radom Test

2013 HIAD TPS Test

2014 Methane Bottle Field Installation, Combustor Pressure vessel recertification

2015 Boeing Aerojet T-3 Aero Test, Lockheed Heat Pipe Test

2016 Boeing Aerojet T-3 Aero Test (2nd Entry), Missile Defense Agency (MDA) IDF Arrow 3 Nosecone Test

2017 ATK P-11, P-11B Hypersonic Air Breathing Weapons Concept (HAWC) Engine Test Lockheed Martin Missile Control Nosecone and Gin Test

2018 Low Mach Transition (LMT) Engine Test, Northrup Grumman Heavy Free Jet 2 (HWFJ2) Engine Test

Referents:

Karen Berger-AST, Position: Aerothermodynamics, Facility Manager 8ft High Temperature Tunnel,

Email karen.t.berger@nasa.gov

Phone: (757) 746-0756

Jason Healy, Position: Assistant Branch Head, SUPERVISORY EQUIPMENT SPECIALIST

Email: william.j.healy@nasa.gov

Phone: 757.864.6527

Stephen F. Harvin- AST, Position: 8ft High Temperature Tunnel Engineer

Email: Stephen.f.harvin@nasa.gov

Phone: (757) 864-7773